It goes without saying that this year has been a challenging one for all of us. This year at Certified Transmission we had seen the number of requests for the 8-speed transmissions increasing to the point where we needed to do our R&D in order to prepare for building these units and bringing them into the market. Our NUR (New Unit Rollout) process is detailed; I can't speak for other remanufacturers but at CTR we take this pretty seriously as a small mistake on the front end of this process can have catastrophic results on the back end. My role in this process is on the vehicle side of things and not inside the unit. We have many people involved in the NUR process, from the core purchases to the finished product that ships out the door. We have already been producing the 845RE and we are still working on the ZF8HP70. We may discuss the latter in a later article, as the topic of this article is the development of the GM 8-speed 8L45/90 units.

The first thing that happens is that we buy a vehicle that we use for testing purposes. For this project we had procured a 2017 GMC Sierra with a 6.2L engine and the 8L90 transmission.

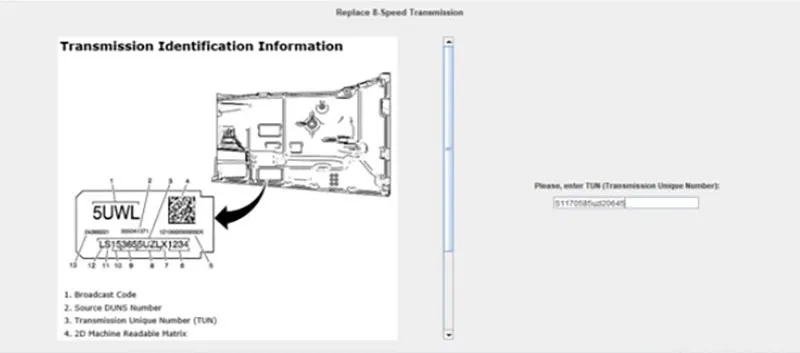

Figure 1

We removed the original transmission and set it aside for when we are done with our research, and install either a new transmission if available, or a low mileage "cut out" that we try to keep under 10K miles just so we can establish a data and performance baseline. We record data with a scope that is used for writing our custom dynamometer tests, record scan data, and then drive for a few hundred miles so we can get a feel for how everything works. The next step really depends on the unit, if there any inherent issues, or TSBs that address a specific issue. On this unit we wanted to move to the valve body first as we had noticed some wear areas in some of the cores we purchased, and there were not a lot of fixes for this in the field.

When the valve body is replaced on these units, programming in the new PUN (Part Unique Number) that is associated with that specific part is a requirement. I know this has been discussed before by people that are a lot smarter than I am. Steve Garrett for one has talked about this unit for a couple years now and has brought us some great information. What I wanted to try to stress is for anyone installing one of these transmissions is how important completing the drive relearn procedure is.

The transmission we installed in our test vehicle was an almost new transmission that was working about as good as these units are capable of. We installed a brand new valve body from GM into it, programmed the PUN, and completed the fast-learn procedure (which takes about 5-6 minutes to complete) and we just successfully turned a transmission that was working really well into a transmission that you would think was on its last leg. On the initial road test, the unit basically neutralized on the 1-2, had horrible flares on the 2-3, 3-4 and 4-5 shifts, a partial bind on the 5-6, and a very bad clunk when slowing to a stop. Going through a normal (or what used to be normal) drive relearn, after driving about ten miles the transmission started working to the point where it did not feel like it was going to leave me walking down the highway, but it still did not work very well. I have seen the drive relearn procedure from GM and it has been talked about at seminars, but hey, I have been doing this for a long time so it has to drive out of it, right? Well the short answer on that is no, it absolutely will not. Back to the drawing board. Time to restart the whole process.

Please refer to the GM Bulletin, 16-NA-019. A quick Google search will reveal a couple sources to get the bulletin aside from a SI subscription, and NHTSA is where I usually go. When I reread the bulletin I realized something that did not register with me the first time I read it. I will use the C2 as an example; this is taken directly from the bulletin:

To Learn C2 (For 6-5 Shift)

- Pressure Learns: Note: It is recommended to utilize a road with a speed limit 40-45 mph (64-72 km/h) for this procedure.

- Perform 10 normal mode 6-5 coast down shifts (zero/light brake) to learn the C2 Return Spring pressure.

- Volume Learns:

- Shift the transmission into 8th gear with the PRNDM in the M position. Obtain an engine speed between 1000 and 1750 rpm. Maintain this condition for a total of about 5 miles (8 km). Cruise control may be used and has been found to result in faster learning of the clutch values.

See where it says to learn the "C2 Return Spring pressure"? This is what I feel creates the need for the system to have to specifically learn an individual clutch. In addition, something we found out while installing a few different transmissions into the same vehicle is that this process is MUCH more important and necessary when you have programmed the PUN. The TUN (Transmission Unique Number) programming will already contain some of this information, that is at least until you start changing parts inside the unit! These specific drive relearns will be needed on any suppliers' unit unless you are buying a brand new transmission from GM. Those won't be available forever, so getting used to performing these specific drive and clutch relearns will be commonplace in the very near future, if not already. Next, we installed one of our reman units into the truck to see how it performed. The first one we built was also a fairly low mileage unit and were able to keep a lot of it together. Programming the TUN on this one did fairly well.

Figure 2

I still had to relearn the C5 which in itself was not easy to do in an urban area, and it will be more of a challenge in larger cities. The second transmission we installed was in pretty bad shape; a lot of parts were changed, programming the TUN doing the QL and normal drive relearn was not going to cut it on this one. I concentrated on the specific clutch relearns for the specific shifts that I was having issues with, and that's how GM recommends addressing these issues. From what I had discovered, the transmissions work best if ALL of the clutch relearns are done. Start with the "pressure learns" first, and then move on to the "volume learns". These procedures require a deliberate test drive, driving to an area where these specific procedures can be completed. Let's be honest; trying to drive at 39mph in manual 6th gear for five miles without stopping on a level road is a challenge, and that is just the pressure learn for C1! However, these procedures are absolutely necessary to make these units work and avoid customer complaints for shift feel.

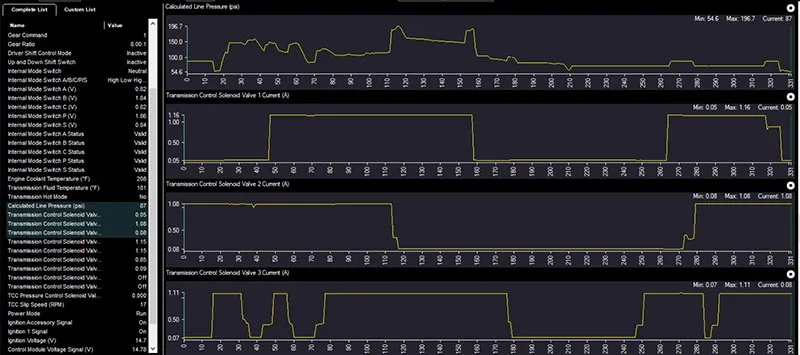

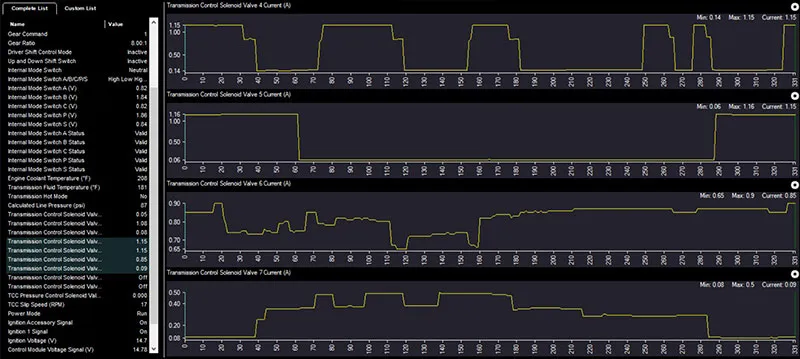

Here are some screenshots of scan data we took from a 0-65mph-0 test run:

Figure 3

Figure 4

In closing, these development steps help us better understand how to perform the correct procedures in the field. We provide a detailed installation sheet with the instructions that we have determined to work best with the units we produce. As the OEM continue to raise the bar on these complexities, it's up to us to learn how to make their technologies work in the aftermarket.

Certified Transmission

Certified Transmission