Sometimes despite your best efforts you can still manage to shoot yourself in the foot. The following account is a prime example of this; while this happened on one specific vehicle, it could happen on any number of vehicles where the cause is the same, but could have different end results.

One of our shop locations had a 2011 Jeep Patriot that came in on the back of a tow truck. The customer stated that it started making noise and then quit moving. This one was an easy checkout; the vehicle didn't move in any direction, had metallic-looking fluid, a horrendous bearing noise, and had a P0777 (secondary pressure control solenoid stuck on) code stored. Even though this one was pretty much a slam dunk in the way of diagnosis, we still needed to go through our complete evaluation procedure.

The Jeep is equipped with the 2.4L engine backed up by a JF011E CVT transaxle (the Nissan version is the RE0F10A). Since we started remanufacturing the CVT applications these transmissions have been selling really well. The Service Advisor contacted the customer and let them know the results of our evaluation, and how much the completed job would cost. The customer agreed to the repairs and the remanufactured unit was installed. After a R&R is completed, the job then gets handed off to me. One of the things we do in our evaluation is check to make sure the software calibration is current, and this one was not. There were updates to both the ECM and the TCM.

Each of our locations have a subscription to the Tech Authority website that we use for service information and programming, and we use the FCA J2534 software and a Snap-On pass-thru pro +4 to complete the required reprogramming for these applications. The next thing that needs to be done on these units (can be done before or after programming) is to initialize the CVT transmission with a capable scan tool, and in this case we use the Snap-On Zeus workstation. After the transmission is installed the TCM will set a P167A (calibration mismatch) DTC. This procedure only takes a couple minutes from start to finish, and then you can either clear the DTC or after a couple ignition cycles the code will go away on its own.

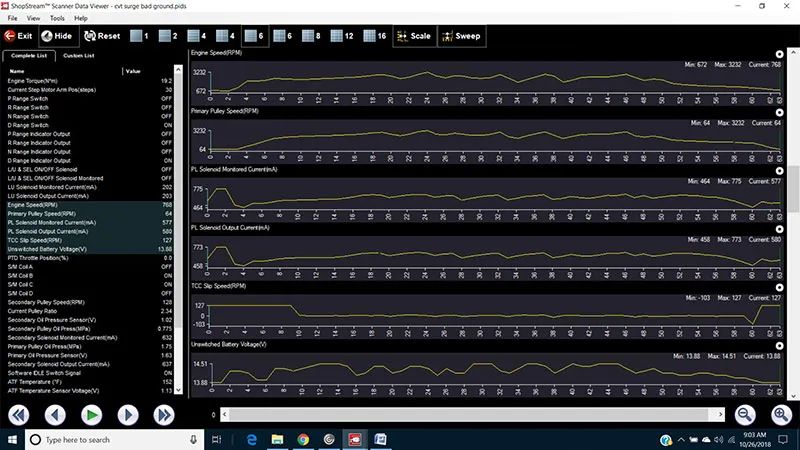

Now we were ready for the road test. It didn't take long to notice that we still had a problem as the vehicle had a really bad rolling surge. I immediately returned to the shop so I could check the fluid level, hoping that maybe we didn't get the fluid level to full, but this was not the case; the fluid was at the correct level. I took the scan tool and set up a custom data list of all the PIDS I thought I needed to look at, and went for another road test. This time I had an associate drive the vehicle so I could watch the scan data, and the vehicle was still exhibiting the rolling surge. Watching the scan data, I could not see anything that was causing it. I could see the results of the surge, and I could see what I thought was causing the CVT to surge, but I just could not comprehend why.

I could see that the PL solenoid monitored current and output current were going right along with the engine RPM and the primary pulley RPM, but was this the cause of the surge, or a result? I still did not see anything that would cause this, so I scrapped the custom data list and just brought up the entire PID list for the TCM instead. While the data updates at a slower rate when you are looking at so much data simultaneously, I had to do something different.

This time I conducted the road test without the aid of an associate and recorded a movie as the issue was happening. I reviewed the data when I got back to the shop. This time I could see a potential cause; the "unswitched battery voltage" was erratic and varying in output at right around .4 volts (figure 1).

Figure 1

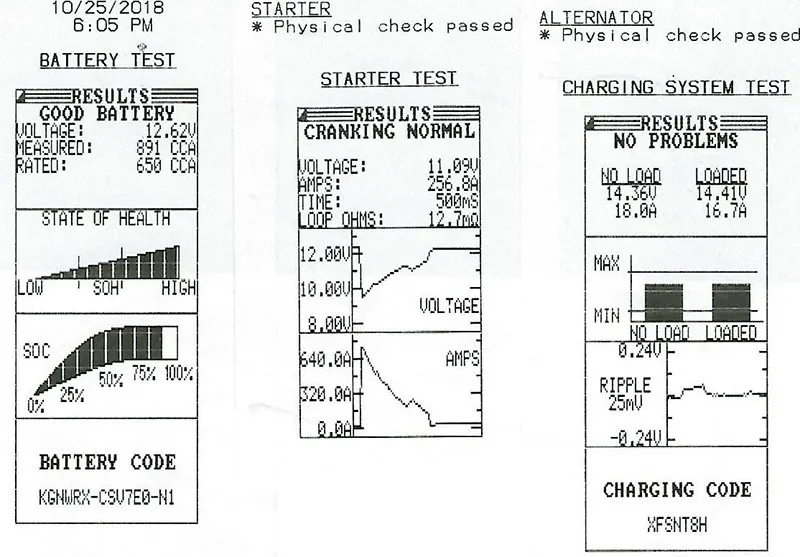

Next, I needed to see why this is happening and if this is the cause of the surge. Another part of our evaluation includes a battery and charging system test, and we use a Midtronics ESP-1000 analyzer which has been proven to work very well and even does a pretty accurate ripple test. I re-ran the test and everything passed. (figure 2) Not wanting to leave anything to chance, I hooked up the scope and looked at AC voltage, and even with that the ripple was at an acceptable level. The thing that did catch my attention was that the zero point seemed to be in somewhat of a wave. At this point I was checking voltage drop on the ground side. When I removed the air intake tube so I could get to the main battery ground cable on the starter bolt, I saw this: (figure 3)

Figure 2

Figure 3

The technician attached the main battery ground up to the throttle body bracket that is mounted with rubber bushings on each side, rather than to the starter bolt right next to it. We moved the cable over to its proper location and the voltage drop looked good everywhere I had checked, so now it was time for another road test.

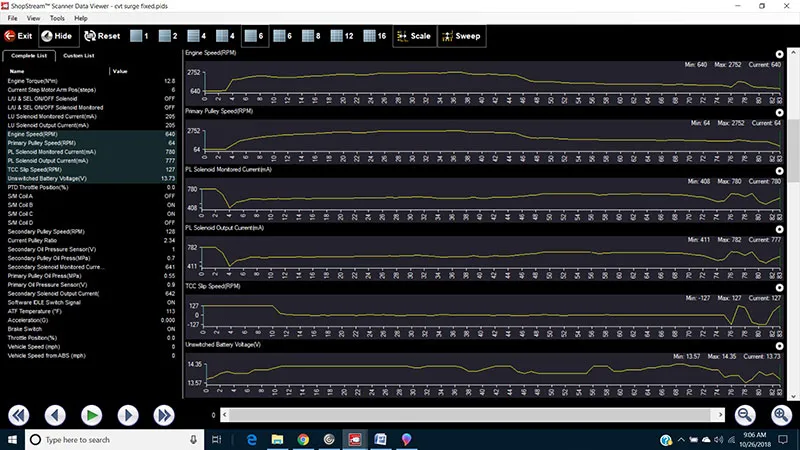

I could immediately tell that the problem was fixed, so I took another recording so I could use this case as a training tool with our technicians (figure 4).

Figure 4

The PL solenoid current was smooth as was the engine and primary pulley speed. There were still some unswitched battery voltage irregularities but they were not affecting the operation of the transmission. I am suspecting that there might have still been some issue with the alternator function, but I have not had another one of the same vehicle that I could compare it to. I think we have all had our tails kicked by a bad ground, but this one had so much of a mechanical feeling effect of the operation of the unit that it really surprised me.

My initial reaction to this when I was driving it was that I was going to condemn the remanufactured unit, as I think it would have been a fairly easy call to make. As the manufacturers are adding more complexity to the electronic controls inside the transmission in the way of more solenoids and even pumps for the stop/start systems, the electrical current required to run the transmission keeps increasing. This in turn will require the entire electrical system to be in perfect working order to keep everything working as it was designed.

Certified Transmission

Certified Transmission