It may seem like common knowledge to check fuses and lights to ensure everything can and does operate properly, although it is sometimes the most overlooked basic check in the automotive repair field. In my own personal experience, I have made this same mistake potentially costing me a lot of time while diagnosing technical issues. In one such case, I was working on a 2009 Kia Sportage with the customer complaint of very hard engagement when shifted into drive or reverse. First, I confirmed the complaint, and that the unit was commanded into failsafe mode. High line pressure was a result of this and causing the harsh engagement. I had scanned for codes coming up with P0707 (transmission range sensor circuit low).

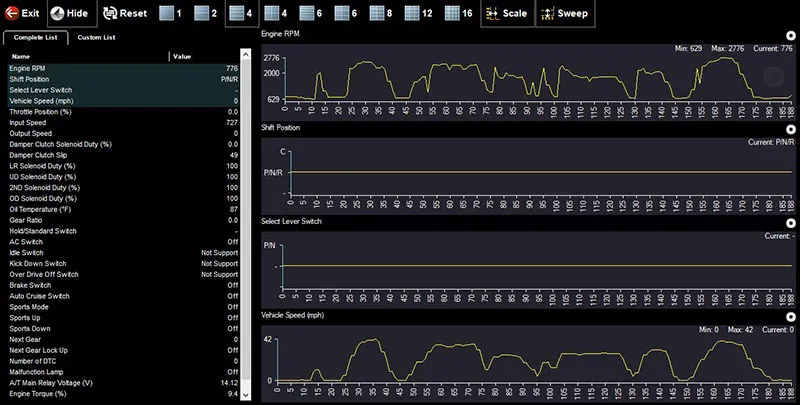

This code can be caused by many different failures; the switch itself can be malfunctioning, the power or ground circuits can be compromised, etc. I then started doing a little more investigating into my scanner data and had found the transmission range sensor was not changing position on the scanner while going through the gears. (Figure 1)

Figure 1

Just to be sure, I tried clearing the code to see if it would start to work, but the code had come back instantly. To make sure that the data I saw was correct, I decided to check it with a different scan tool. The results were identical. I was going through a mental checklist of the information I had gathered. I completed an entire check of the wiring and everything that was visible, making sure the switch was plugged in and in good condition.

After completing all the checks, I determined that I would need to check the internal condition of the transmission and the range sensor. I then got to work on this basic job, first checking the fluid which was old and dark red, but still nothing to tell me the transmission was in bad mechanical condition. I started working on the range sensor, double checking it and all the connectors and wiring to see if I could locate a point of failure. I got everything back together after verifying that there was nothing obviously broken or damaged.

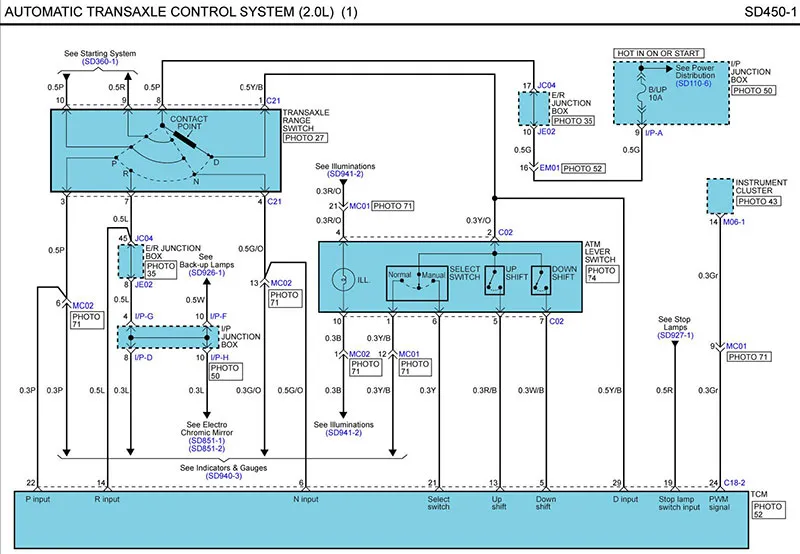

I grabbed my scan tool, cleared the codes, then started the vehicle. I went from park to reverse and it clunked really hard again, and the same thing going into drive. I then rescanned the vehicle and found no codes were reset. At this point I was confused, trying to come up with a solution to where I had gone wrong or missed something. I tried doing more research on Identifix for a solution but was not able to come up with anything. I then started with another mental checklist and realized I hadn't checked the fuses. I thought surely there is no way a fuse might cause this issue; it was likely a bad switch. I figured just to amuse myself I would go ahead and check the fuses, so I printed off the diagrams.

I started looking the diagrams over and found the fuses I was going after. I went to the vehicle and found the fuse boxes. After looking at the diagrams I determined that the fuse box I needed to look into was the one on the side of the instrument panel. I pulled the cover off and started looking it all over and found what I thought was a missing B/UP (backup/reverse light) fuse. I grabbed a 10-amp fuse put it where it needed to be and retested again. I cleared the code and moved the shifter from park to reverse and no hard engagement. I went through the gears several times just to ensure that it was fixed and sure enough it was. I felt very relieved that I finally had figured it out and we did not have any other bad parts.

Figure 2

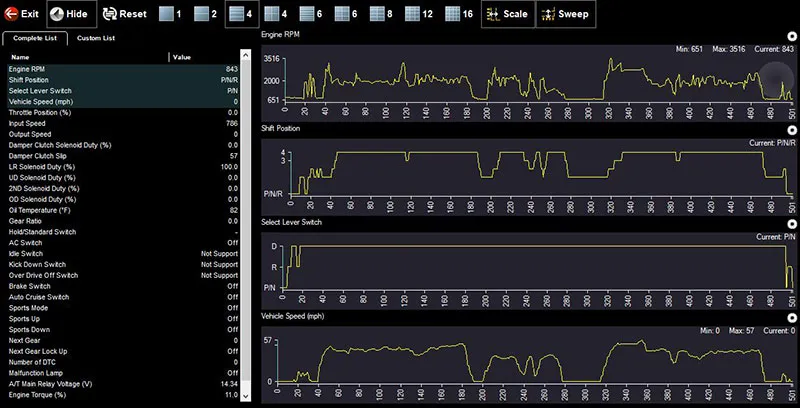

Figure 3

I removed the fuse again with the vehicle off and put it into reverse and had no reverse lights. Replaced the fuse and put it back into reverse with the key on and we had reverse lights. Had I checked the lights before I would have realized that I had no reverse lights and that may have led me into the fuse box a lot sooner.

The next question in my mind was why the B/UP fuse had been removed in the first place. My first inclination was that the fuse had blown at some point, and the vehicle owner removed it with the intent to replace it later, but never did. After driving and testing, the fuse did not blow again, so at this point we will have to wait and see what happens down the road. If the vehicle should come back to us with the same symptoms, I know what I'll be checking first.

Whether this should be chalked up as a rookie mistake or not is up to you to determine. The automotive field is always about learning from your mistakes. Since I have only been in the automotive field for approximately six years, I still have a lot of learning to do and I'm sure a lot more mistakes like this one. I have always been told in this job you will never stop learning. There is always a lesson to be taught whether it is from a more experienced technician or learning from your own experiences. Hopefully, this article will help a technician save some time at some point and keep them from having to waste time on an easy fix. One thing I have taken away from this experience was to always make sure that checking the lights and fuses should always be a part of my diagnostic checklist.

Certified Transmission

Certified Transmission