The first vehicle was a 2019 Nissan Sentra that arrived with a severe drivability complaint: slipping, whining, and eventually a complete loss of movement. Initial diagnostics revealed two transmission-related fault codes: P0868 (Fluid Pressure Low) and P17F0 (CVT Judder). Fluid inspection showed it was full but burnt, indicating internal damage. We recommended replacing the CVT with a remanufactured unit.

After installation, however, the vehicle exhibited harsh engagement into reverse and a five-second delay into drive, followed by a bang and limited movement. New fault codes appeared: P0846 (Transmission Fluid Pressure Sensor/Switch 'B' Circuit Range) and P0965 (Pressure Control Solenoid 'B' Circuit Range/Performance). Attempts to perform the auxiliary clutch relearn failed, and the codes persisted.

At this point, the diagnostic path pointed toward an internal transmission fault. Before initiating a warranty claim, we verified power and ground integrity, confirmed communication with the PCM, and ensured all connectors and sensors were properly seated. Everything checked out, so we proceeded with a warranty replacement.

The second unit improved slightly-engaging gears and moving-but still had a delay and struggled to reach speed. Again, P0965 returned during the relearn procedure. The odds of two remanufactured units exhibiting identical faults were slim, prompting a deeper inspection.

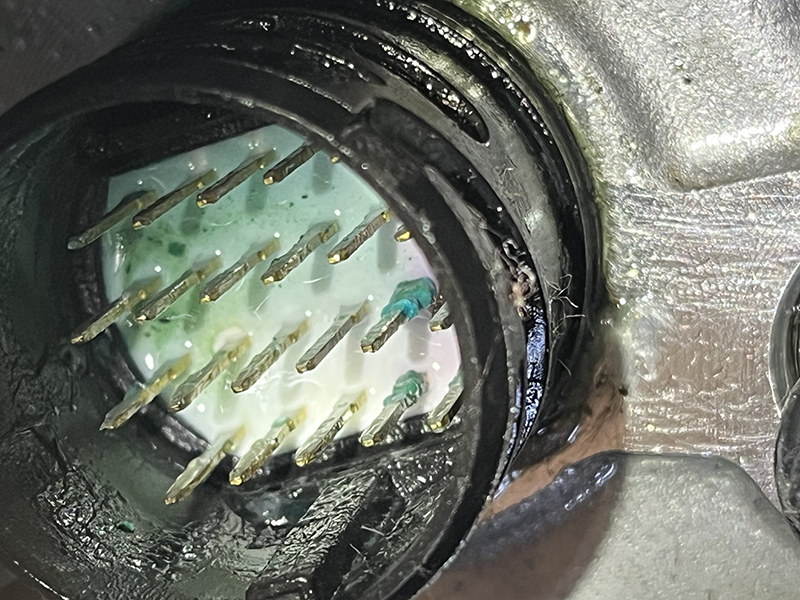

This time, we removed the main transmission harness connector and discovered green corrosion on the lower pins. (Figure 1)

Figure 1

After cleaning the connector and applying dielectric grease, the transmission began functioning correctly. The relearn was completed successfully, and the vehicle was finalized and returned to the customer.

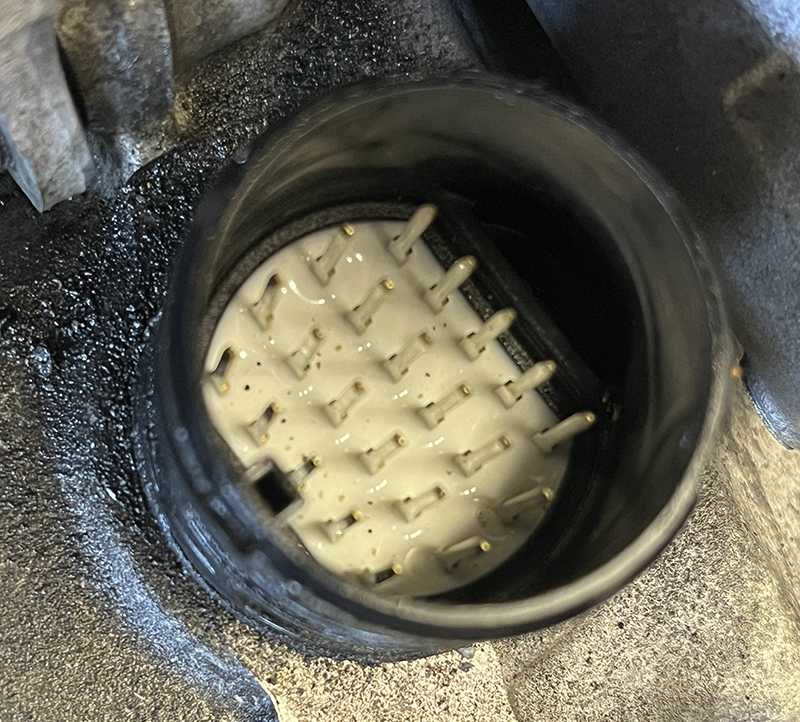

To validate our findings, we inspected the case connectors on both units. The original transmission was clean. (Figure 2)

Figure 2

The second unit showed multiple corroded pins and standing transmission fluid inside the connector. This confirmed that the issue was not with the vehicle's wiring but with the remanufactured unit itself. We reported the condition to the warranty department for further evaluation.

Case Study 2: 2011 Jeep Grand Cherokee - When Grounds Go RogueThe second vehicle was a 2011 Jeep Grand Cherokee that arrived in fail-safe mode with a laundry list of fault codes: P0882 (TCM Power Input Signal Low), P0846 (Transmission Fluid Pressure Sensor/Switch B Circuit Range/Performance), P0871 (Transmission Fluid Pressure Sensor/Switch "C" Circuit), P0988 (Transmission Fluid Pressure Sensor/Switch \"E\" Circuit Range/Performance), P0876 (Transmission Fluid Pressure Sensor/Switch D Circuit), P0706 (Transmission Range Sensor Circuit Range/Performance), P0716 (Transmission Input/turbine Speed Sensor Circuit), P0721 (Transmission Output Speed Sensor Circuit Range/Performance), and P1764 (Direct Clutch Solenoid Valve). The sheer volume and variety of codes suggested an electrical fault rather than a mechanical one.

After clearing the codes, the vehicle drove normally for about five miles before reverting to fail-safe. The pressure switch codes returned, prompting us to begin circuit testing. We back-probed the power supply from the Totally Integrated Power Module (TIPM) and the return wires at the PCM. With the key on, voltage was present. However, closing the hood caused a voltage drop-a repeatable event.

Further testing revealed that tapping on the TIPM consistently caused voltage fluctuations. The wiring appeared intact, so we recommended replacing the TIPM. After installation, the voltage drop issue was resolved, and the vehicle drove for nine miles without triggering pressure switch codes.

However, new codes emerged: P0706 (Transmission Range Sensor Circuit Range/Performance), P0716 (Transmission Input/Turbine Speed Sensor Circuit), P0721 (Output Speed Sensor Circuit Range/Performance), and P1794 (Speed Sensor Ground Error). All are related to range and speed sensors. A review of the wiring diagram revealed that while pressure switches were powered through the TIPM, the range and speed sensors were controlled by the PCM via the G4 connector.

Upon inspecting the G4 connector, it detached with minimal force-without releasing the clip or safety catch. The retaining clip was broken, and the connector was not seated properly. (Figure 3)

Figure 3

We ordered a connector kit, re-pinned it, and secured it to the PCM. After clearing the codes and performing a final road test, the vehicle operated flawlessly.

Lessons Learned: Diagnosing Beyond the CodeThese two cases highlight a critical truth in modern transmission diagnostics: fault codes are only the beginning. In both instances, the initial symptoms and codes pointed toward internal transmission failures. However, deeper investigation revealed that electrical connection issues: corrosion in one case, and a loose connector in the other. These were the true culprits.

For industry professionals, these examples reinforce the importance of:

- Thorough connector inspections, including pin fitment and corrosion checks.

- Understanding power and ground pathways, especially in systems controlled by modules like the TIPM or PCM.

- Avoiding assumptions based on fault codes alone and instead using them as a guide for deeper diagnostics.

In an era where electronic control systems are increasingly complex, the ability to diagnose electrical faults accurately is as essential as mechanical expertise. These cases serve as a reminder that sometimes, the fix isn't in the transmission; it's in the connection.

Certified Transmission

Certified Transmission