In the automotive repair industry, we often encounter cases that test the limits of diagnostic persistence. When a customer brought their 2000 Ford Explorer Sport to our shop with a recurring transmission issue, it was clear this would be one of those challenges. What made this case particularly intriguing was that three other shops had already examined the vehicle without resolution. It was up to us to dig deeper, think critically, and uncover the root cause of the problem.

The Customer's ConcernThe customer's primary complaint was that the transmission stopped shifting after driving on rough roads. The frustration was palpable - they had been to multiple repair facilities, each unable to identify the problem. The customer also provided documentation from a previous shop, which described their findings. According to the report, fuse 13 in the battery junction box (BJB) - responsible for the transmission solenoid - would blow when driving on rough roads. However, when the transmission solenoid pack was unplugged, the fuse remained intact. The earlier shop suspected a shorted solenoid pack but couldn't confirm the diagnosis.

Initial Inspection and TestingOur investigation began with the basics. Checking for diagnostic trouble codes (DTCs) yielded no results; the vehicle had no stored or active codes. A visual inspection revealed no obvious issues, although we did note several transmission leaks. The transmission case connector showed no signs of fluid intrusion, eliminating that as a potential cause.

Next, we took the vehicle on a standard road test. The transmission operated normally, with no signs of malfunction. Extending the road test, we ventured onto rough gravel roads and city streets, monitoring the transmission with a scanner. Once again, the transmission functioned flawlessly, and no DTCs appeared. At this point, we advised the customer that we couldn't replicate the concern but noted the transmission leaks as a separate issue.

Determined to find answers, we decided to conduct additional tests. On the second day, we drove the vehicle for 20 miles over similar road conditions, albeit on different routes. The results were identical: normal transmission operation with no codes. Despite the lack of progress, the customer agreed to let us perform one more extended road test.

Figure 1

Figure 2

On the third day, after approximately 15 miles of driving, the "Check Engine" light illuminated. Interestingly, the transmission continued to operate normally. This time, a self-test revealed code P0155: HO2S Bank 2 Sensor 1 Heater Circuit Fault. Checking fuse 13 in the BJB revealed that the fuse had not blown. This development added a new layer of complexity. Could the oxygen sensor code be related to the original transmission issue?

Delving Into the Wiring

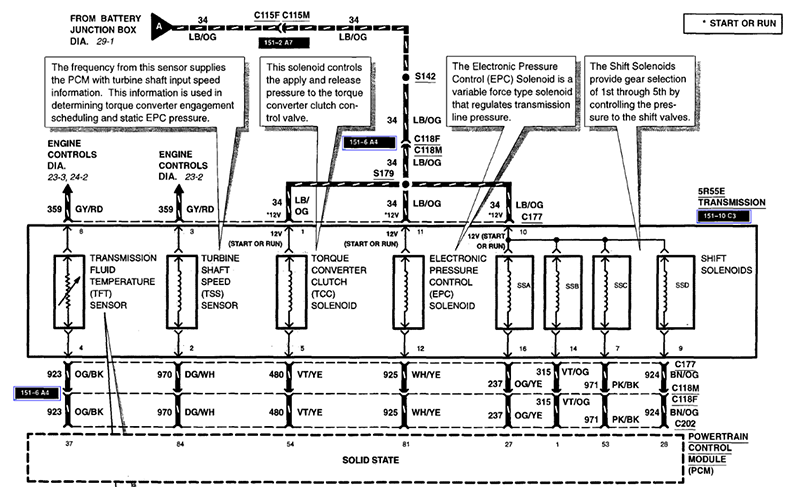

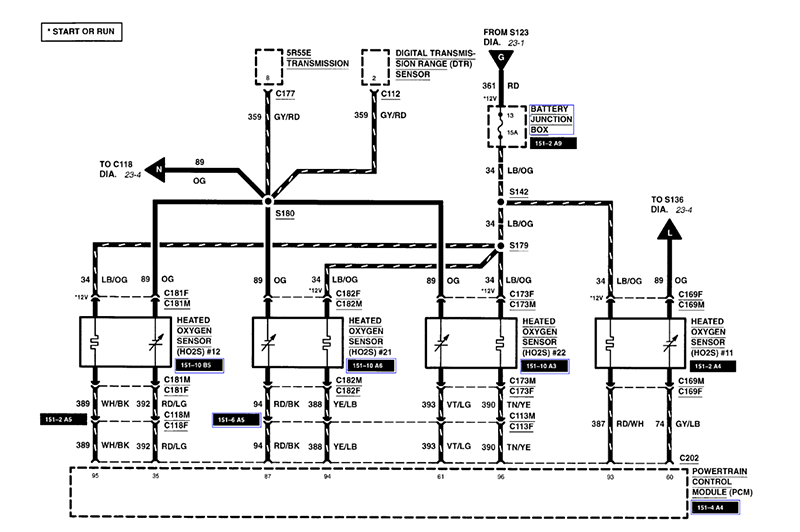

With the new information in hand, we began examining wiring diagrams to identify any potential commonalities. Fuse 13 protected several circuits, including the heated oxygen sensors, EGR vacuum regulator, EVR solenoid, camshaft position sensor, canister vent solenoid, and the automatic transmission.

We inspected the wiring for the Bank 2 Sensor 1 oxygen sensor heater circuit and discovered a loose exhaust heat shield resting on the sensor's wires. (Figure 3) Closer examination revealed that the power-side wire of the heater circuit had been severed, likely causing the fault code. While this explained the P0155 code, it didn't clarify why fuse 13 was blowing or how it affected transmission operation.

Figure 3

Digging deeper, we scrutinized the exhaust heat shield. Two distinct electrical burn marks provided the breakthrough. One burn spot was where the shield had contacted the oxygen sensor wire; the other was where it had been rubbing against the front driveshaft. On rough roads, the shield vibrated against the driveshaft, creating an intermittent short that caused fuse 13 to blow. The P0155 code emerged when the shield completely severed the heater circuit wire.

At this point, the entire picture came into focus. The intermittent short in the heater circuit, caused by the vibrating heat shield, was triggering fuse 13 to blow. Although the transmission itself was not directly malfunctioning, the loss of power to the circuits protected by fuse 13 disrupted its operation, leading to the customer's initial complaint.

The ResolutionArmed with this understanding, we proceeded with the necessary repairs. We replaced the damaged oxygen sensor and removed the problematic heat shield. A final road test confirmed the success of the repairs: the transmission operated normally, fuse 13 remained intact, and no new DTCs appeared. Satisfied with the outcome, we returned the vehicle to the customer, who has since reported no further issues.

Key TakeawaysThis case underscores the importance of persistence, thoroughness, and critical thinking in automotive diagnostics. It also serves as a reminder that seemingly unrelated components can have cascading effects across a vehicle's systems, particularly in older models with high mileage. In this instance, a loose heat shield - a relatively minor issue - led to a chain reaction affecting both the oxygen sensor and the transmission circuits.

As vehicles age, wear and tear can manifest in unexpected ways, making diagnostics more challenging yet equally rewarding. For technicians, this case serves as a valuable lesson in the importance of investigating every detail and considering how interconnected systems can influence one another. Ultimately, our ability to solve such puzzles not only helps customers but also deepens our understanding of automotive systems and their complexities.

Certified Transmission

Certified Transmission